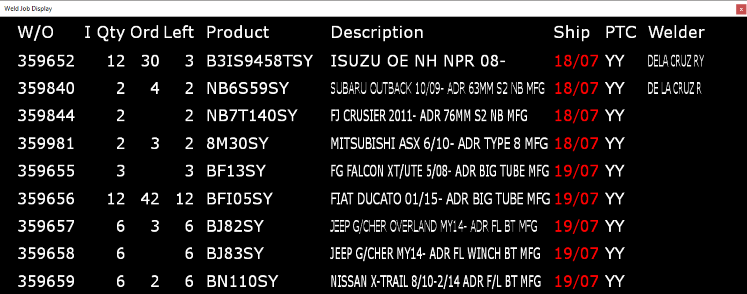

Welding Job Display

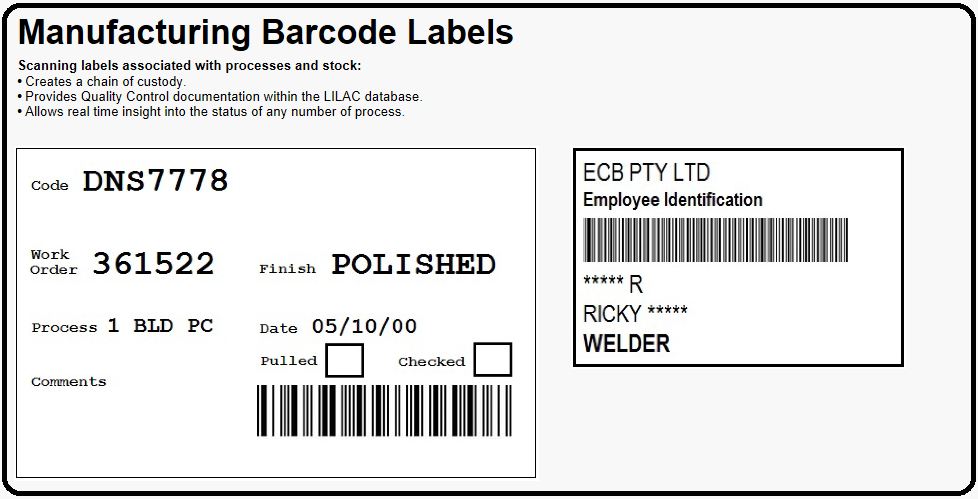

Barcoding

LILAC supports barcode and label printing on a variety of stationary and layouts:

Capturing relevant information:

Capturing relevant information:

• Paper

• Polymer Plastic

• Cloth

• Adhesive

• Tag with Hole

• Tag with Tail

• Thermal or Direct Transfer

• Polymer Plastic

• Cloth

• Adhesive

• Tag with Hole

• Tag with Tail

• Thermal or Direct Transfer

• Materials

• Processes

• Weights

• Location

• Destination

• Etc

• Processes

• Weights

• Location

• Destination

• Etc

Manufacturing

Monitor:

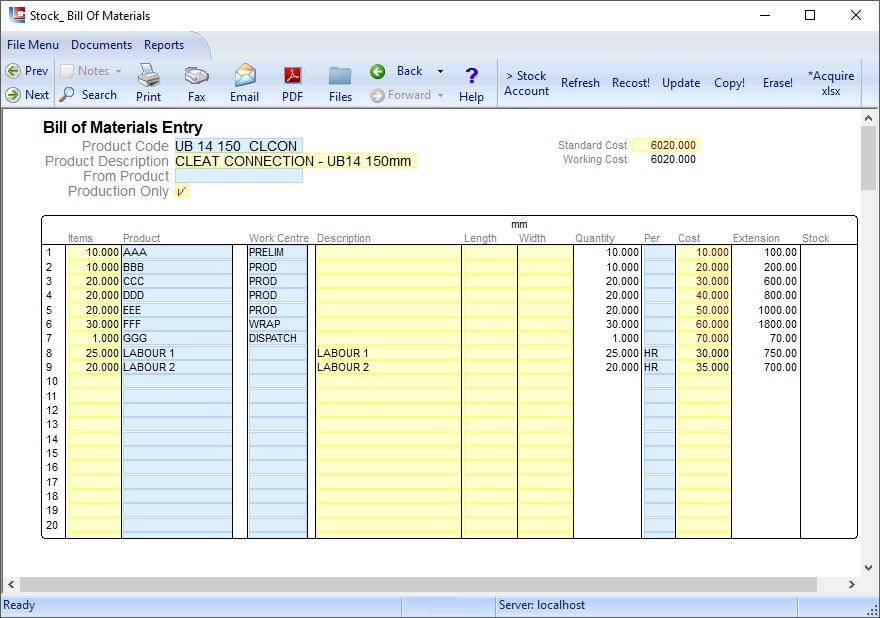

Any product may have a Bill of Materials defined, allowing for the creation, storage, and editing of a list of components.

The generation of a Work Order checks stock levels, and if desired, registers or reserve stock components contained within the bill of materials. Automatic component requistioning can be established for component stock items found to be below minimum levels.

BOMs can be configured at a single level, and contain sub-assembly or nesting.

Any product may have a Bill of Materials defined, allowing for the creation, storage, and editing of a list of components.

The generation of a Work Order checks stock levels, and if desired, registers or reserve stock components contained within the bill of materials. Automatic component requistioning can be established for component stock items found to be below minimum levels.

BOMs can be configured at a single level, and contain sub-assembly or nesting.

Lennox Computer LILAC Business Software

6/333 Queensport Rd North MURARRIE QLD 4172

Brisbane, Australia

http://www.lennox.com.au

Brisbane, Australia

http://www.lennox.com.au

ERP Business Accounting Software

Distribution, Manufacturing, Timber

Phone: 0418 886 912

Est. 1980

| Contact Us | Downloads | eCommerce | Demonstration Software |

LILAC Manufacturing Software - Scheduling & Production

Plan, Track, Display, and Report

•

Scheduling

• MRP - Material Requirements Planning

• Staged Manufacturing Work Centres

• Status

• Inventory

• Freight

• Records and Detailed Reporting

Combine core Accounting, Order Processing, Invoicing, Payroll, and Reporting functions

• MRP - Material Requirements Planning

• Staged Manufacturing Work Centres

• Status

• Inventory

• Freight

• Records and Detailed Reporting

Combine core Accounting, Order Processing, Invoicing, Payroll, and Reporting functions

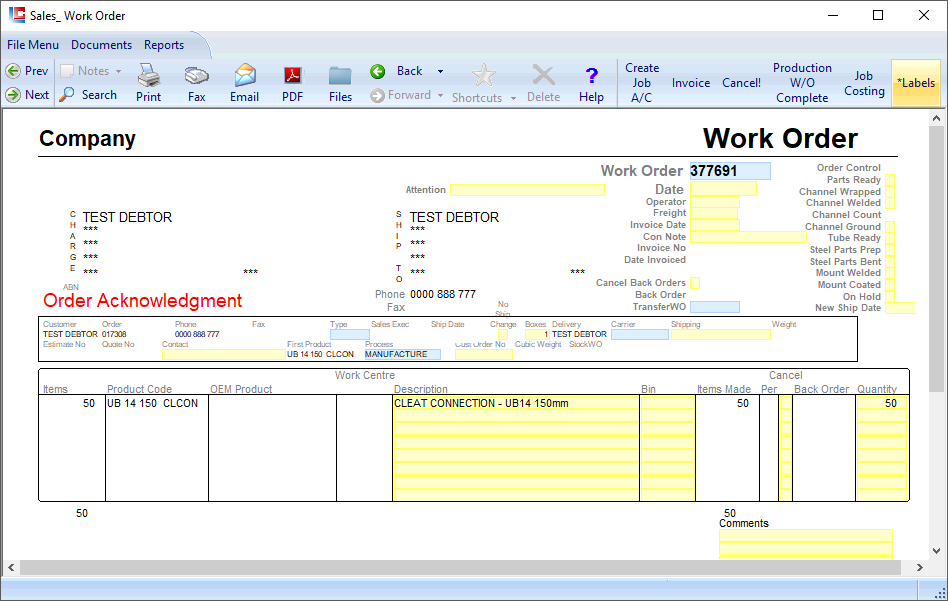

Work Order Manufacturing Control

Sales Orders or Internal Production Order generate Work Orders. A Work Order can be paper, card, or digital - available or displayed at any location. Work Orders serve as the control document for manufacturing.

LILAC captures data in production environments through any combination of barcode scanning, touch pads, or keyboard entry - associated with a particular Work Order. Confimation data fed into a Work Order in the manufacturing process regulates the production proccesses, providing an electronic paper trail for management, reporting, and analysis, and a permanent historical chain of custody.

This process is suitable in many applications.

LILAC captures data in production environments through any combination of barcode scanning, touch pads, or keyboard entry - associated with a particular Work Order. Confimation data fed into a Work Order in the manufacturing process regulates the production proccesses, providing an electronic paper trail for management, reporting, and analysis, and a permanent historical chain of custody.

This process is suitable in many applications.

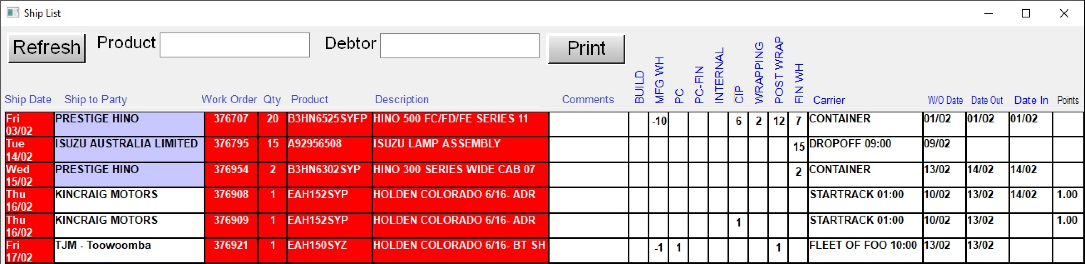

Multiple Work Orders Displayed - Scheduling & Quality Control

Work Orders can be complimented by one, or several, large screen display boards located throughout a production area, dispatch area, or office setting. Digital boards display selected schedule and manufacturing information. Capturing and storing data digitally allows progress management without interruption or excessive paper logging.

• Product

• Status

• Shipping Date

...any required information

• Product

• Status

• Shipping Date

...any required information

• Bill of Materials (BOM)

• Material Requirements Planning (MRP)

• Material Requirements Planning (MRP)

• Materials

• Quantities

• Dimensions

• Descriptions

• Costs

• Assembly Processes

• Quantities

• Dimensions

• Descriptions

• Costs

• Assembly Processes

Integrated CAD

Technical information and diagrams including codes, images, descriptions, BoM listings, and schematic diagrams with dimensioning can be integrated into a Work Order.

On-Site Barcode Printing

Barcode scanning is used extensively in modern manufacturing, distribution, wholesale and retail situations. LILAC Software provides extensive support for the production, printing and scanning of a multiplicity of barcode formats in an extensive array of applications.

LILAC provides off-the-shelf functions to print EAN and other format barcodes for product labelling, processing, inventory, and freight applications.

LILAC provides off-the-shelf functions to print EAN and other format barcodes for product labelling, processing, inventory, and freight applications.

Lennox Computer are well positioned to provide barcode solutions for manufacturing, distribution, or trading enterprises.

Whole of Enterprise Integration

LILAC is tailored to suit businesses and organisations large and small, centralising operations to an accounting ledger, integrating the management of business processes.

Procurement

Stock/Inventory

Manufactured Product

Work Centre

Data Collection

& Live Display

Data Collection

& Live Display

Purchase Order

Sales Order

Barcode Scan

Product & Material Use

Work Centre 1

Product & Material Use

Work Centre 1

Barcode Scan

Product & Material Use

Work Centre 2

Product & Material Use

Work Centre 2

Purchase Invoice

Sales Invoice

Accounts Payable

Accounts Receivable

Scheduling

General Ledger

Picking, Packing, Freight

Work Order

Reporting

Payroll

Quotation

Estimate

Bill of Materials

Lennox Computer - 07 3267 7880

Brisbane, QLD, Australia.

Brisbane, QLD, Australia.